One way to tell if a pilot is serious about his responsibility to conduct a thorough preflight is if he looks at a propeller, notes that it’s still attached and walks right by it to the other wing’s fuel drains. Even if it’s a relatively simple all-metal, one-piece, fixed-pitch affair, things can go wrong with it. If it’s a constant-speed or reversible model, it also has a lot of parts in the hub that retain and actuate its blades.

And it has a tough life. It’s often first to the scene of an incident, for example, and if it’s not properly secured or maintained, it can fail in spectacular ways, throwing blades and shaking engines out of their mounts. A few props have even decided to take the “goodbye, cruel world” route and departed the airplane entirely. It doesn’t have to be that way.

Hubs And Spinners

In between scheduled inspections and maintenance, the pilot is front and center when determining if a propeller remains airworthy and if it needs attention. It’s not hard to do a thorough preflight inspection on a propeller, but there are a few things you might not be looking for, or even recognize when you see them.

One of the first things we need to do before inspecting a propeller, however, is ensure there’s no way moving it can start the engine. With that in mind, you can’t move it if you don’t touch it, or at least if you don’t turn it. Even if with the keys in their pocket, people have been killed outright when the prop being inspected suddenly came to life. The moral is to treat every propeller as if it can start turning at any time.

Instead of turning the prop, and with it the engine, propeller pros recommend a four-step preflight test. First, try to move the prop blade fore and aft. Second, attempt to rotate the blade in its hub (fixed-pitch props need not apply). Third, push and pull the blade toward and away from the hub. Finally, try lifting and pushing down on the blade. If you succeed at any of those tasks, have someone competent take a closer look.

With that out of the way, the typical GA propeller has a spinner, often a one-piece metal cone secured to a round bulkhead mounted behind the prop. A series of screws attach the spinner to the bulkhead. The screws obviously should be present and secure, something it might be hard to verify without turning the prop. Don’t. Bend from the waist and use a flashlight if needed. Try to wiggle the spinner fore and aft. If it moves, it’s not properly secured.

You’re also looking for cracks in the spinner material, especially around the mounting screws. Thanks to wear and tear, older spinners may have slightly enlarged mounting holes; a loose screw may promote so-called “smoking,” where the metal around the screw exhibits a dark gray material. That’s aluminum oxide, a form of corrosion, and it means the screw (or rivet, for other aircraft components) is moving slightly. The same thing can happen between the spinner’s interior surface and the attaching bulkhead’s outer mounting rim.

It would be odd for a fixed-pitch prop to exhibit oil streaking—if it does, get a mechanic to look at it—but it’s more likely with a constant-speed/reversible model. If you do spot oil streaks or even a thin film, that’s a possible sign of a cracked hub, or at least a bad internal seal. Again, someone competent should examine it more closely.

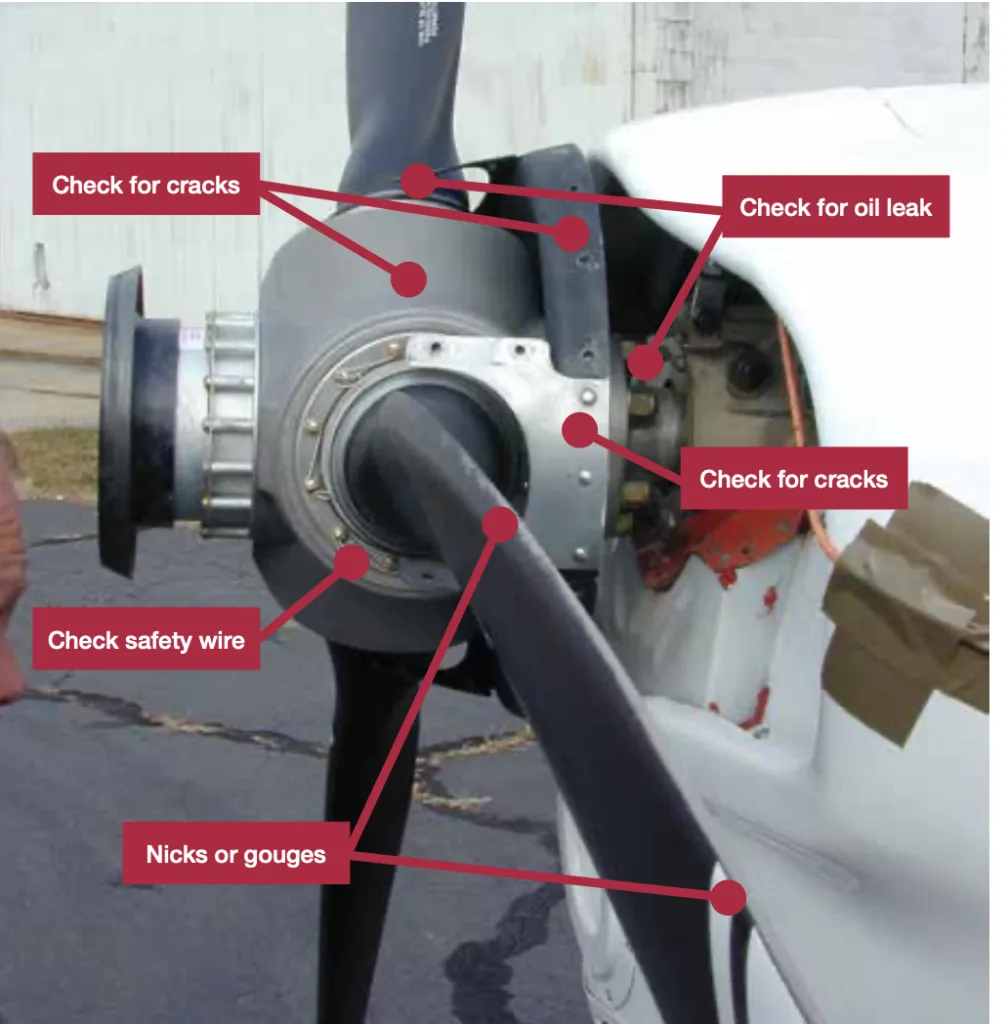

The vast majority of constant speed/reversible props have spinners installed. Many fixed-pitch props, like the one pictured at the bottom of the opposite page, don’t. That helps you perform a complete inspection because you want to make sure the bolts remain tight and that the safety wire hasn’t been disturbed.

Any time a prop’s spinner isn’t installed, like in the image at upper right, is a good time to take a close look at those mounting bolts. It’s also a good time to examine the hub for signs of corrosion. Some hubs may have a high content of ferrous metals, so instead of smoking or white powder, they’ll exhibit plain old rust.

Blades

Propeller blades are airfoils turned 90 degrees to the oncoming air; they’re flat on the back side and have a curved front side, which is thick at the hub and thin at the tip. Just like a wing, leading edge contamination like bugs, or pitting from rain and/or corrosion, can reduce the blade’s efficiency.

As with propeller hubs, blade corrosion is especially problematic. Blades typically are painted with a high-quality coating to help prevent corrosion, and any missing paint will tend to promote it. For that reason, some manufacturers suggest keeping a light coat of oil on the blades. Also for that reason, you’ll spend a lot of time maintaining a polished prop.

Run a finger lightly over the prop’s leading edge to check for roughness and corrosion. A cheap terry cloth towel is a good tool here; if it snags on a part of the blade, it’s a good bet there’s a nick that needs to be addressed. Nicks with sharp edges can create a stress riser, increasing the likelihood of blade failure. A mechanic can file out shallow gouges.

A lot of foreign material on the blades, or a deep-enough gouge, has the potential to disturb the prop’s balance and increase vibration, which in turn gets transmitted throughout the airframe. Dead bugs or substantial dirt also can promote corrosion. Clean off the blades with an aluminum-friendly liquid, then wipe them down with a light oil.

Despite a propeller’s susceptibility to cracking and corrosion, most shops say pilots who taxi into things are their best customers. Pay attention to where you’re taxiing and slow the engine when over gravel or loose pavement, which is how they get nicked and gouged.

A decent preflight inspection, plus regular maintenance, means you’ll always have a poorly designed handle with which to move the airplane back in its hangar.

This article originally appeared in the August 2020 issue of Aviation Safety magazine.

For more great content like this, subscribe to Aviation Safety!

I had a customer call on a Sunday morning saying his “dawn patrol” flight was canceled because his wooden prop was leaking oil! It was the crankshaft seal of course. Also, the back side of the prop is the curved side, not the flat side. At least that’s the way I learned it as an A&P two generations ago. Agreed, propellers are a much neglected preflight item, and I commend you for your safety comments.

What would be the defintion of an “aluminum-friendly liquid?”

Aluminum Friendly cleaners are any cleaners that do not promote corrosion on aluminum.

For instance, vinegar is an acidic and will promote corrosion on aluminum over time if not thoroughly rinsed off promptly.

Cleaners such as Star Brite Aluminum Cleaner [ Walmart ] are specifically formulated to prevent that, while adequately cleaning.

Just a shout out from your friendly retired technical writer: Don’t forget about the manual. You can download the manual for most props for free. The manual will typically include a recommended preflight procedure, and provide detailed descriptions of no-go items. For example, the manual for my MT propeller lists depth, width, and length dimension for things like dents, cracks, nicks, etc. for different parts of the blade. It also includes pictures for those of you who don’t like to read the words.

The back side of the prop is the curved convex side. The front side of the prop is the flat side. Just as a wing would be.

Uh oh – the angle of incidence of my prop’s blades changes from the root to the tip! Is something wrong? What could happen??!?

“Propeller blades are airfoils turned 90 degrees to the oncoming air” is a misleading and erroneous statement. I realize it was meant to be a throwaway kind of simplification but it ignores the basic design characteristics of a propeller, and it reflects on the writer.

Fixed pitch props have a useful life, as I found out when we removed the 4,000 hr prop from our Cessna 175B for overhaul. On inspection by the overhaul shop, it had a crack in the center bore, adjacent to a bolt hole, and it was in the process of failing.

Our new, overhauled, used prop has ‘prop guard’ tape on the leading edges, [ a FAA PMA part].

After 2 years now, the leading edges are perfect, with no paint loss, so the prop look like new.!!

After reading a couple of the comments, I had this sinking feeling…so I went out and checked my 3 blade McCauley. Sure enough, dagnabit, I’ve been flying my little Comanche for the past 15 years with the prop mounted on it backwards! The convex surface is toward the FRONT, and the flat (flat black) surface faces the pilot! No wonder I’ve only been getting 160 kts TAS instead of the 300 kts I was expecting.

Also, I periodically hear you’re never supposed to move the airplane by pushing or pulling on the prop. I’ve never really understood that, as the prop pulls my airplane from a dead stop to takeoff speed in 60 seconds, which requires a lot more force on the prop hub and crank than I can exert moving the plane around in my hangar. Anyone out there have a rational explanation for that old saw?

The point you’re overlooking in your force analysis is that when the prop is spinning at TO RPM, the blades are exerting huge centrifugal forces outward on the hub. The total force on the blade is the sum of that radial force aligned along the blade and a smaller forward thrust force pulling the blade (and plane) forward. The resulting total force is mainly radial with a small forward inclination. The hub is designed to retain the blades while providing forward thrust while the blades are strongly held in position by the centrifugal force. When the prop is not rotating, the blades may have some play in the hub attachment, and all the pushing or pulling forces from ground handling are backward or forward, torquing the hub in ways that are completely different from powered-up rotation.

Is that really much of a problem? I don’t know; it’s definitely a different loading. I hold on to blades near the hub when pushing or pulling, not out on the skinny sections.

Thinking about the rotational forces on the blades will also explain how airworthy turbine engine blades can make loud clanking noises when shut down but slowly windmilling on the ramp on a windy day. They don’t flop and rattle when rotating at operating RPM unless someone is about to have a very expensive day 🙂

I also grasp the prop near the hub when moving the airplane, but near the tip when preflighting the prop to be sure there is zero play. Any detectable play at all would be a show-stopper for me.

I’ve heard the same admonition about moving a plane with a fixed pitch prop, I presume fearing abnormal stresses on the engine crank. I still doubt the 20 or 30 lbs of pressure I put on the prop when moving the airplane comes anywhere close to forward torque generated at full rpm, irrespective of the tremendous radial forces developed. I gather it doesn’t really concern you anymore than it does me (?)