Electrified: Flying An Electric Xenos

One of the most common questions I received in the nearly seven years I was editor in chief at KITPLANES® was, “Why don’t you ever cover electric aircraft?” The answer we…

One of the most common questions I received in the nearly seven years I was editor in chief at KITPLANES® was, “Why don’t you ever cover electric aircraft?” The answer we always gave was something like, “Well, when there is an aircraft that can be built by the average amateur that can carry more than one small person and accomplish a mission that is more than just ‘once around the patch,’ we’ll write about it!”

Well folks, the time is here. Let’s have a look at the electric Xenos, a motorglider than can carry two full-size adults and stay aloft for over an hour—more if you can find great lift!

There have been quite a few electric-powered ultralights that have flown, and credit goes to their designers and builders. However, in the E/A-B category, electric planes have occasionally been announced, flown a couple of times and then gone silent. Problems with excess weight, insufficient batteries or limited endurance have gotten them all. But the eXenos is different—mostly because it is a motorglider that requires a lot less power to just go have fun.

In my experience with gliders, there are two kinds: those that are designed for competition and efficiency and can be flown long distances for hours at a time, and those that are lower performance and can tire you out after an hour or two of hunting for thermals. The Xenos airframe will never be mistaken for a high-performance sailplane, so it belongs to that second group. And in fact, if you’re not going out to fly sailplanes every weekend, but just enjoy hunting a thermal now and again, you probably belong to that second group as well.

If I look at my quite limited glider logbook, most flights have been fairly short. Even those in motorgliders have been limited in duration, mostly because we were just going up to have some fun. So a flight duration between one and two hours is quite reasonable. After that, I figure I am ready to get back on the ground for a rest and review of what I am doing right and what I am doing wrong. When I reach the point that I want to fly longer in a glider, I am going to be looking at stepping up to one of those high-performance ships—with or without a motor.

So lets take a look at what makes the eXenos so special and how it is to fly!

The Chalk Talk: Let’s Talk Design

Gabriel DeVault’s Xenos started out like any Xenos—a pile of aluminum and a set of plans from Sonex Aircraft, LLC. The original owner made one significant change that we could see: Instead of pulling the standard dome-head skin rivets, he dimpled the entire airplane for flush pulled rivets, a nice touch that can be argued as excessive or just compulsive in the drag reduction department for an airplane designed to fly around at 80 or less knots most of the time. But it does make for a smooth and pretty airframe.

Gabriel picked up the project when it was ready for systems and powerplant—the perfect spot to begin an electric installation. As a founder of the electric motorcycle manufacturer Zero, he used his 10 years of experience in designing electric power systems and went straight to his roots: He purchased a 2018 Zero motorcycle, used. Unfortunately, but understandably in this litigious world, Zero’s lawyers don’t want the company to be associated with aviation in any way, so you can’t go to them and buy their custom power system components directly. But they don’t have any say in what you do with used parts.

According to Gabriel (and a recent search of used motorcycle websites), you can purchase a suitable donor bike for somewhere around $10,000–$14,000. This is a significant upcharge over what you would pay Sonex for their AeroVee engine, but significantly less than what you would pay for a suitable Rotax or Jabiru—and it’s downright cheap compared to a small Lycoming or Continental. The donor bike will be stripped to provide the motor, battery package, controller and engine monitor display. The package is cleverly designed with a Bluetooth interface that can be used with monitoring apps on your smartphone or tablet. It also has the capability to provide auxiliary 12-volt power that in the bike would be used for consumer accessories. But in the airplane it can power radios, transponders and EFIS displays—just like that alternator you’d find on an aircraft motor.

The basic power package is mounted to a custom engine mount that Gabriel designed and had built. It incorporates the firewall end of the mount supplied by Sonex to retain the landing gear leg sockets and then consists of welded tubing to support the battery and motor. It could be argued that since the battery is the significantly weighty part of the power package, it is really a battery mount that also holds the relatively tiny motor and reduction drive in place. The reduction drive is a simple spindle with a pulley to mate with the cogged belt coming from the motor pulley, as well as a prop hub to which you can bolt the prop. Gabriel is using a Prince prop that came with the Xenos airframe from the original builder. There is nothing custom about it for the electric power in this configuration.

The entire power package weighs in at about 250 pounds, according to Gabriel, and replaces the standard motor and fuel system. With the battery hanging forward of the firewall and the fuel tank removed, the weight and balance comes out very close to a standard Xenos—a major consideration for anyone building with an alternative powerplant. The battery accounts for about 180 pounds of that weight, with the rest being in the monitor, controller and wiring. There are some pretty large wires to conduct that much power around, but they are short. The batteries are 102-volt lithium-ion, the same as used in the motorcycles. And despite the odd rumors we have all heard, there are no reputable reports of Zero motorcycles going up in flames.

No matter what powerplant you choose for an aircraft—internal combustion, electric or nuclear for that matter—you have to deal with waste heat. The motor gets warm, as does the battery, when you decide to flow a lot of electrons through the package. The Zero controller monitors all of these temperatures and will prevent high temps from damaging the components if red lines are approached. And yes, this can happen if a pilot asks for full continuous power until the batteries are dead. The package will protect itself before that happens, however, by rolling back power on its own—after a suitable advance warning to the operator that the rollback is coming.

But rather than let the computer protect the parts, the pilot can do the job by monitoring how much power is being asked for and throttling back when initial temperature limits are reached. The electric motor from the Zero needs to be kept below 300° F. On our flight we kept it in the low 200s, and it was quite easy to do so. In reality, this is no different than managing oil and cylinder head temperatures in an air-cooled internal combustion engine—the pilot has to remain in charge. The controller from the bike does, however, have several different modes that can be selected, such as Sport or Eco. These limit the amount of power that will be used (Eco is obviously “economy”) and provide nice, conservative limits that will still allow the airplane to fly quite well. Sport mode is, well, sportier and will run hotter than Eco mode. In our flying we used Sport mode for takeoff and maneuvering, and Eco for loafing along.

Gabriel said that thermal equilibrium on a standard day comes at about 25 kW demand from the battery—which, amazingly enough, coincides with the top power permitted by the Eco mode—so that is a pretty safe place to fly without having to worry about lots of engine system monitoring.

So how does it perform? Gabriel reports that the airframe’s best endurance is found when flying in the low 60-mph range, which we confirmed in our test flight. We found level flight at near gross weight to take about 9.5 kW from the battery at that speed. The airplane has recorded speeds of 110 mph using 20 kW of power with one person aboard, and Gabriel regularly flies between Hollister and Watsonville, California, (a 22-mile trip over a ridge) using 35% of a battery charge. He has recorded a soaring flight of just over 2 hours using minimal power to supplement average thermals near the airport. Zero Motorcycles lists the standard battery pack as having a 14.4 kWh capacity, and it’s not hard to do the math to figure out how long you can last at a given power level. Fortunately, the computer does that for you and shows remaining percent power at all times.

One of the exciting things you can do with the airplane as a motorglider is to let the motor provide any level of power you want as an assist. In effect, it’s a “dial a lift to drag ratio” system. You can set the power for level flight in stable air, then go looking for lift to give you a climb rate above that. You can, of course, shut the motor down entirely and soar the way John Monnett, the designer of the Xenos, intended—on pure wing alone, mano a mano against the elements. Or give the wing a little help when the thermals aren’t as strong, and go blasting past those hawks circling for altitude in the rising air.

While it is hard to imagine a sport plane, such as an RV, using existing power to conduct flights the way you can with internal-combustion energy, the power package is almost ideally suited to a recreational sailplane—something to go enjoy for an hour or an hour and a half. It’s a significant step beyond the electric ultralights that have preceded it, and yes, many steps behind a 170-knot RV that can go 600 miles on a tank of gas. But it is a step nonetheless and a practical one (for recreational purposes) at that.

Gabriel reports that he currently has 80 hours on the airplane, and it has been flown by a number of pilots, carrying many different passengers. That, in our book, makes it a viable two-seat motorglider. He reports that the power system has performed flawlessly, and they have yet to have an emergency. On the very first launch, before proper ducting had been crafted, test pilot Bob Mackey thought he was going to run into an engine thermal limit on takeoff and need to make a single circuit—but he throttled back and flew the plane for 45 minutes. As we said, thermal management isn’t a problem; it is just something to get used to.

Building It

Gabriel started his project with what could best be described as an “ultra-quickbuild” airframe. In other words, he picked up a project that was close to completion by another amateur builder. The original builder put quite a bit of time into the airframe, deciding to dimple and flush rivet the entire thing. As someone who has built my own Xenos to about this point, that is an impressive amount of extra work! I didn’t spot anything that wasn’t good, quality workmanship, so it formed an excellent basis for Gabriel’s powerplant application.

The power package is from a salvaged Zero motorcycle, a vehicle that Gabriel helped design. He purchased a used bike from an online sale and removed the motor, controller, batteries and the necessary accessories to make the whole thing go, transplanting them onto the airframe. The motor is actually relatively small compared to the battery pack, and it hangs at the front of the motor mount, just below a spindle that holds the actual propeller hub and pulley, which are driven by a toothed drive belt (the same type as used in the motorcycle) off the pulley on the motor itself. It’s an elegantly simple design, well suited for the relatively low power needed to fly the motorglider.

The Xenos is typical of many taildragger sport planes since the engine mount also provides the sockets for the steel landing gear legs. So despite the fact that Gabriel needed a different mount for the battery and motor, he still needed the part that held the gear to the firewall. He started with the existing mount and cut away the part intended for the original motor. He then added what was needed to support the battery pack—essentially in the original space behind the motor—and the ears on which to hang the motor from the Zero motorcycle. The prop spindle is mounted above that on a special weldment and bearings designed for the task.

Everything in the power system (except for the charger display, and throttle control) fit under the cowling, forward of the firewall. That leaves a lot of space aft of the cowl where the original Xenos fuel tank would go. Surprisingly enough, the CG worked out almost exactly like it did for the original gasoline-powered motorglider with about a half tank of fuel, according to Gabriel. Getting the CG right is always tricky when adapting an alternative powerplant to any aircraft, so when it works out right off the bat, that’s a huge win!

Gabriel’s next challenge was providing cooling air to the motor. Even though it isn’t burning hydrocarbons, it still generates waste heat. He glassed over the original cooling air intakes on either side of the prop hub because they didn’t direct air anyplace useful and carved a hole below the prop, directly in front of the finned electric motor. Because there was no risk of fire due to fuel and oil, he was able to mock up a cooling shroud to direct air where it was needed out of cardboard—and he is now fabricating a fiberglass duct based on the paper prototype. Our flight was still with the cardboard ducting, but we were able to fly the mission we wanted without excessive concessions to heat management.

There were almost no other changes to the airplane aside from omitting the fuel tank, and nothing else changed behind the firewall. This fact is attractive to anyone that has a flying Xenos and is looking at doing something different by going electric—or for someone who has reached the airframe-complete stage and is finally getting around to mounting a motor. The changes can be done with little backtracking.

Overall, we’d rate the degree of difficulty of building the eXenos to be about that of building an IC Xenos: It’s different, but probably not more or less challenging—and it’s possibly cleaner because you don’t have any of those liquid hydrocarbons to spill. Electrics do have some advantages in this regard!

Let’s Fly!

The eXenos is fundamentally a simple airplane despite the hi-tech appearance of the electronics. The airframe is easy to preflight; there are few exposed fasteners to check. Walk around and check for loose parts and that’s about it. There’s no oil to check, no fuel tanks to sump. I guess you can look for a puddle of brake fluid under each wheel if you feel compelled to look for fluids!

Getting into the cockpit is simple: Swing over the standard Sonex side-hinge canopy and settle yourself into the left or right position. Each stick has a push-to-talk, and that’s it. There are no brake pedals on the rudder pedals; the airplane has a single brake lever on the stick that activates the hydraulics for both wheels simultaneously.

In addition to the throttle handle on the left side of the cockpit, there’s a spoiler handle—familiar to glider pilots, maybe a little more mysterious to power-only pilots. Spoilers are not speed brakes; they simple spoil lift and don’t add much drag. There are no flaps on the airplane, but if you find yourself high and need to come down, pop the spoilers and you’ll generate lots of sink without causing a loss of speed.

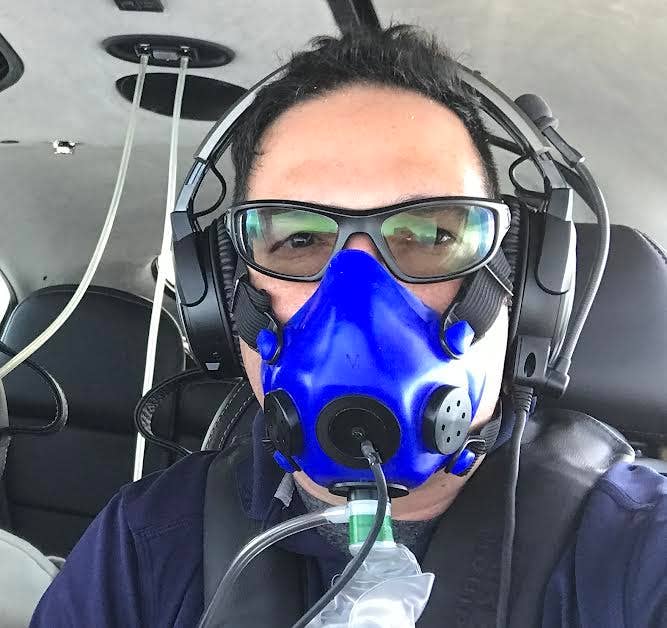

N540EV has a simple instrument panel: a large analog airspeed indicator, a compact variometer for soaring (which also serves as an altimeter), a small radio, an ADS-B equipped transponder—and the instrument cluster from the motorcycle that donated the motor to the airplane. That is pretty much all you have to look at, along with an iPhone that sticks on the panel and runs an app that gets its data from the motor controller through Bluetooth. Obviously, a homebuilder can design whatever they like for their panel, but this assortment does well for the prototype proof-of-concept airplane.

Once you’re strapped in and put on the headphones, Gabriel asks, “Are you ready?” and a quick look around shows that there isn’t anything else to do. He flips on the power switch, and now all it takes to get going is to move the throttle forward. There isn’t any start procedure and no warm-up. Just push the throttle forward and the prop starts spinning. Steer with the rudder/tailwheel and use the hand brake to control speed. What I found unnerving the first time it happened was that when we came to a stop, for instance at the hold-short line, Gabriel pulled the throttle all the way back and the prop just stopped. There’s no point in having it spin “at idle” if you’re not moving and no reason it should do so either!

The plane was ready to go with a wiggle of the flight controls, a check that the spoilers were closed, the canopy latched and the traffic clear. We trundled out onto the runway (I always think of long-winged motorgliders as trundling about on the ground; make sure you watch those taxiway lights and your wingtips!), lined up, made a radio call and off we went!

I wasn’t sure what to expect, but the takeoff actually felt astoundingly normal. We gained speed about as I remember when flying the factory AeroVee-powered Xenos several years ago and broke ground at a respectable 50 mph. The initial climb was less anemic than with many popular gas-powered training aircraft; we were 500 feet up by midfield and close to pattern altitude shortly after passing the far end of the runway. Big wings make airplanes fly, and the Xenos certainly has a big wing (as anyone who has ever straightened all the ribs for a set of Xenos wings can testify).

Gabriel handed me the aircraft after we turned downwind, and thankfully there was no slip/skid ball to show my footwork after several years of not flying long-winged aircraft. Like most gliders, you have a little different coordination job than with short-winged sport planes, but it comes back to you fairly quickly. I was flying from the right seat with no throttle, so we used “voice commanded power” when I had the stick, and that worked well. Once we found the sweet spot for our weight—the point where we had enough power to maintain level flight, but no more (so that we could truly fly on thermals, or sink in between them)—we went looking for rising air.

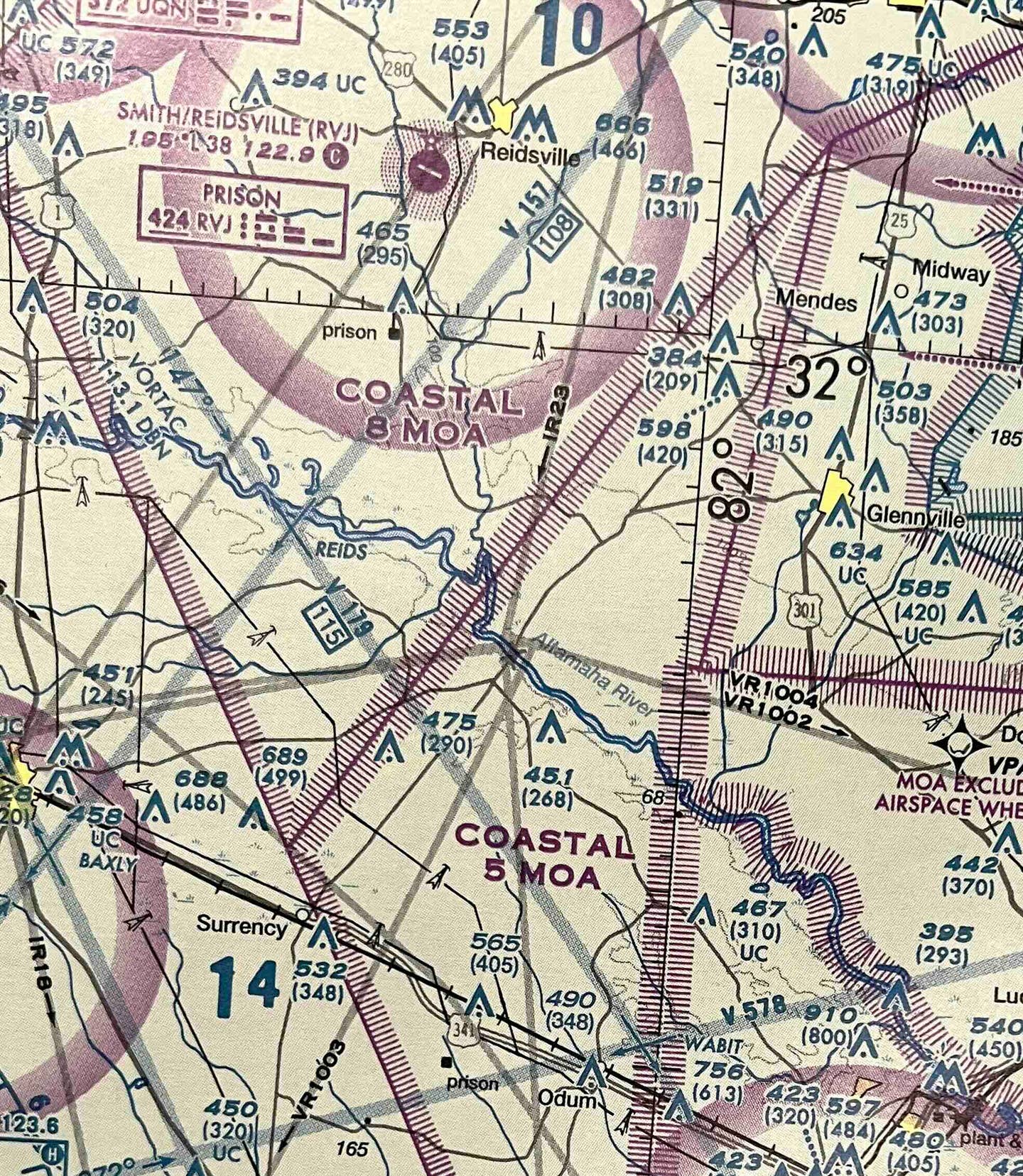

The airplane flew exactly like the Xenos I had flown before. You know right off the bat that you have to give the wingtips time to get out of their own way in a turn! Hollister airport is located in flat terrain and surrounded by farm fields, many of which were generating rising air for our entertainment. But we weren’t the only ones being entertained—there were thermalling birds to look out for—and to follow! The birds know a free ride when they see or find one, so we joined a couple in their pursuit of altitude and really didn’t have to use many of the electrons we had stored for our flight.

The glider was happy around 60 mph. It was also happy to go faster with more power, but that speed worked well to minimize sink and find some altitude in the thermals. Slower and the nose got fairly high as we fell onto the backside of the power curve. Faster and we were using more power than necessary. Gabriel has made a combination soaring/motor flight that lasted two hours already, which is quite an accomplishment when compared to other electric aircraft that are flying.

Motor management is a fairly simple matter of keeping temperatures within limits while generating the appropriate amount of power for what you are trying to do. It should be noted that the motor controller is quite sophisticated and won’t let the pilot damage the powerplant. When it reaches a redline temperature, it will automatically power itself back—something that needs to be in the pilot’s mind as they fly. This isn’t really a problem if you stay ahead of the airplane and avoid spots where you absolutely, positively must have full power “Right now!” to survive. Since this is a fair-weather sailplane, you are unlikely to be in such a spot unless you are getting too close to rising mountainous terrain. Stay ahead of the airplane, watch the instrumentation, and you’ll stay away from the edges.

We stayed close to the field on this demo flight because we found good lift right there; we had no need to venture far afield. But it was easy to keep an eye on the battery status if we had decided to venture farther out. When we were done with the sample mission, we still had 70% showing on the battery capacity meter as we crossed midfield and turned downwind for landing. I set us up unfortunately high, forgetting those long wings, but Gabriel had the spoiler handle out early, and we touched down easily on the aim point and made the first turnoff. The prop was turning throughout the approach, but it could just as well have been stopped and the airplane flown as a pure glider. I find that in flying motorgliders, using both power and spoilers in combination allows for very precise glide slope control and makes for more precise touchdowns. There is also less chance of float with the long wings in ground effect if you have the spoilers out.

The taxi back and shutdown were just like the takeoff—simple and quick. Drive the airplane to the place you want to be and pull the throttle back to stop the prop. Open the canopy and get out—you’re all done. You just push the airplane into the hangar, grab the charger cord and plug the plane in; in an hour it’ll be ready to go again if you drained the battery pack. It’s quicker if you leave more juice in there. Our flight, at close to gross weight, lasted about 24 minutes, and we used a little less than a third of a charge—and we weren’t trying to conserve. If we’d flown a typical “slightly less than an hour,” we’d have had a lot of fun and not fully drained the “tank,” which for my generation, looking at the history of electrics, is impressive.

My biggest question before flying this, my first electric-powered flight, was how will it sound? Well, truthfully, it still makes noise. The Xenos is an all-metal airplane that rattles a bit at different frequencies that can be excited by prop rpm and wind speed. So no, it isn’t silent. But shortly after the flight, I found myself at the fuel island, fueling my RV for the trip home, and someone running up a Mooney about 50 feet away was really starting to get on my nerves. I realized then that I was already beginning to think about how soaring flight is so much quieter—and electric soaring flight is the next best thing.

Is It Safe?

Probably the first question most pilots will ask when the conversation turns to electric airplanes is going to be about the safety of those batteries. “Well, didn’t you hear about the Tesla that caught fire on the freeway?” Yeah, there is that Tesla that occasionally catches fire.

“Well, I’ve been an RV modeler all my life, and I’ve seen what happens when one of these new electric-powered airplane batteries overcharges and puffs up! It’s bad! Lots of smoke and sparks!” Yeah, I’ve had that happen with a couple of cheap, small, rechargeable model helicopter batteries.

“Well, have you seen the video of that Cub that had the lithium battery fire? It generated all this toxic smoke and melted the case; I sure wouldn’t want to have one of those in my airplane!” Yup, I’ve seen that one as well—even investigated it a bit—and it isn’t quite what you think. But the concerns are all still valid and deserve to be answered.

So first, let’s state up front that “Is it safe?” is actually a poor question to ask in aviation, especially Experimental aviation. The short answer is, “No, it’s not safe; you can get killed in an airplane!” The better answer is that you’re asking the wrong question. The right question is, “Is this more or less risky than what we have already accepted?” Compare the new risks to those that you fly with every day and see where you stand.

I checked into the Zero motorcycles that provide the motor and batteries for the electric Xenos. No one could point to a fire or explosion incident that could be verified. This isn’t that surprising when you consider that vehicles sold for highway use have to meet a certain set of government standards—something our E/A-B aircraft don’t have to do. But no, these motorcycles aren’t out there as flaming torches, destroying riders and the rest of the world.

But how about in the airplane—how do I compare it to the traditional gas-powered system? Well, we all know that one of the complaints about electric airplanes is that they don’t have the endurance or total stored power that a gas-powered airplane has. That’s true because the energy density (joules/lb) of gasoline is much higher than that of batteries. If we all accept that fact, then the stored energy we carry in the airplane is actually less for an electric than it is for gas power.

Now let’s look at the electric Xenos. In the gas-powered version, the 18-gallon fuel tank is located behind the firewall, above the pilot’s and passenger’s legs. It is a poly tank with no fire containment. In the electric Xenos, the battery is located forward of the firewall, hanging from the motor mount. (In fact, that welded tubular construction should really be called the “battery mount.” The weight of the motor is negligible compared to the battery pack.) So tell me: If you had a fire in the “energy storage device,” where would you rather have it—inside the cabin with you, or on the other side of the firewall?

What about power failures? Most pilots have trained all their lives for what to do if the engine quits. You can try a restart on a full tank of gas, but if that doesn’t work, you are pretty much a glider and looking for a place to land. There isn’t much difference with electric power. If the motor quits for any reason, you’re a glider—just the same. The good thing is that if you’re flying an electric Xenos, you are already flying a glider! This is why an experimental electric powerplant is such a good fit on a motorglider. As we learn about how to make electric power better, why not give ourselves the best odds while we figure out its reliability? Recreational gliders regularly operate fairly close to their home airport anyway. (I’m not talking about the serious competition guys that are willing to fly half a continent away to set records and win pins for their achievements.) The average “go out and soar a little while” pilot like me generally stays pretty close, so they don’t have to worry about landing out in a field and having to deal with a retrieval. So if the engine (either gas or electric) on your motorglider quits, just go ahead and land. It doesn’t get much safer than that.

Is It Ready To Try?

Regular readers of KITPLANES® might remember that my wife and I have had a Xenos project in the workshop for several years. It gets attention when all the other airplanes are in flying condition and aren’t undergoing modifications or maintenance. Right now, the Xenos is at the stage where the structure is finished, the AeroVee engine has been built and hung on the mounts, and a little bit of the plumbing and wiring has been completed. There is still a lot of cowling and baffling work to be done, as well as finish work on the canopy and cockpit.

In short, it is at almost exactly the right point to think about converting it to electric power. If we were any further along, we’d have a lot of work to throw away. But at this point, it’s simply a matter of unbolting the engine, modifying the engine mount (which realistically means replacing it and remounting the main landing gear) and then beginning installation of an electric power package.

That’s one of the “problems” of being an aviation journalist—you find out about things early that might be interesting! So naturally, the question in our household is, “Should we consider switching to an electric Xenos? Is it ready for prime time?”

Well, the answer to the second question is a little tricky because no—it is not ready to buy a single box with everything you need, along with complete drawings and plans to tell you how to do it. The real question then should be, “Is this a project that can be completed without a great deal of extraordinary effort?” To that, I think the answer is a qualified yes.

Qualified because we are fairly close to Gabriel, geographically; he’s just across the single mountain range from our home. That means while there may not be instructions, there is an existing airplane with a power package that can be photographed and copied. There is also Gabriel himself available to answer questions and give basic guidance. And we have a fairly complete shop in which we can make necessary parts. So yes, the project is quite possible. But remember—this is true experimental homebuilding, going beyond the kit by quite a bit. There are always going to be stumbles along the way.

The pros and cons are lengthy, and you should consider them carefully. In the building category, the most important con is to recognize that this is not a firewall-forward kit. There is only one prototype, and Gabriel is not in the business of selling finished packages. He is available for collaboration on projects and will be supplying a few components that will make things quicker—but don’t expect to build one like a piece of IKEA furniture—you’re going to have to do your homework.

The major pro for building is that it is a clean project—you’re not going to be messing around with much in the way of petroleum products!

From an operational perspective, one of the biggest pros is that the airplane is ready to go as soon as it is charged up, and it is dirt-simple to operate: Turn on the power and advance the throttle. Throttle back when you don’t need power. Fly it like a Xenos, and you can do “power assisted” soaring very easily. There is plenty of instrumentation to tell you the state of the battery and powerplant, so it is different—but not hard—to manage.

There’s another pro that is large but hard to quantify: You are truly advancing the state of the art every time you fly and contributing to the experience base. It is real Experimental aviation!

In terms of cons, probably the most obvious is that endurance— and hence range—is limited compared to a gas version. The standard 18-gallon tank, if filled, will give you 3 hours of flying (plus reserves) with an AeroVee or Jabiru up front. The record so far with the Zero drive, with a generous use of thermals for lift, is 2 hours. Unless you add batteries, it probably doesn’t get much better than that. So you either have a local flyer, or you have to plan your cross-countries so that you know where you can recharge and how long that will take.

It all comes down to how you want to use the Xenos and how far off the reservation you’re willing to go in doing something different. And as always, the answer will be different for different people.

—P.D.

A Chat With Gabriel DeVault

What’s really involved with using Zero motorcycle components in a Xenos? Paul Dye asked Gabriel DeVault the following questions.

Dye: Tell us how hard it is to pull the Zero motorcycle apart and get parts for the aircraft—is it as simple as unbolting components?

DeVault: As with most things, it seems intimidating at first but is actually pretty simple. I can pull the entire drivetrain and electrical bits out of a motorcycle in less than a full day. The battery is heavy and requires an engine hoist and some straps to manage safely. The battery is loaded from the bottom of the bike, so you actually set the whole bike and battery on a stand and then lift the bike off the battery.

Dye: How much do you have to do in terms of new wiring? Does the harness come over from the bike, or do you have to build new wiring—and is it large wiring or just signal-level stuff?

DeVault: In the Xenos configuration, the only “required” modification is to extend the control switches and wire in a new throttle—unless you want a moto throttle on your plane! There are about a dozen small wires you have to lengthen. You can leave the ABS unit, turn signals, and brake lights and wiring intact if you want. But assuming most will not want or need them, you simply follow those wires back to where they branch out of the harness and snip them off. Because of the compact firewall-forward configuration, all of the main cabling stays intact. Depending on the charger you use and where you install it, some fairly simple cable lengthening may be required.

Dye: What kind of outlets do you need for charging? Will a person need to install a special charging station in their hangar to recharge, or can you interface with standard 110-volt sockets?

DeVault: The stock Zero motorcycle comes with a 1 kW 110/220VAC charger. This will plug into any normal wall socket and charge your bike/plane in about 8–12 hours. I highly recommend the Zero Motorcycles “charge tank” accessory, which charges at 6 kW and will charge your plane in 2 hours or less. You can use any standard J1772 car charger with it. These can come with ends to fit any 110–240 outlet, though your charge rate will be reduced on 110 VAC. I recommend something like the MustStart Level 2 Portable EV Charger (https://tinyurl.com/47p6mbv2) as you can buy any selection of plugs, and it’s small enough to take in the plane. That’s what I have. Plus you can use it for your electric car or motorcycle.

Dye: What kind of options are there for charging? Are there special chargers for quicker charging, and do they need special circuits in the hangar?

DeVault: See above. Any 220-volt 30-amp or better outlet will work. The NEMA 14-50 is the EV nerd standard and provides plenty of margin and general compatibility. I hope to see 14-50 plugs made available at all public airports for aircraft charging. This is the most open and democratic way to enable charging and won’t require specific charger types or accounts or payments.

Dye: What’s the best way to find a donor bike?

DeVault: First, I would only recommend a 2018 (or later) SR or DSR with the “charge tank” option. This has all the best battery, motor, controller and charger options. When possible I would encourage you to buy a new bike from a dealer. Floor models and year-end specials can get the prices pretty good. And you can probably get various federal, state and local incentives as well!

You can buy used and save a few thousand bucks, but it introduces uncertainty: You never know how the previous owner treated the bike and battery. Every part has a finite life, and I’d like for as much of that to be available for my use. Craigslist or one of the motorcycle classifieds can be a good source for used bikes. You can find wrecked bikes for auction at IAAI or Copart, but I do not recommend it. It is highly risky, and you will not get support from any dealer, Zero Motorcycles or myself, when it doesn’t work.

My final advice: Don’t try and scrimp! Any decent airplane project is going to be expensive, and trying to shave a few thousand bucks on the most vital part is not a good idea. It will still be cheaper in the long run than many possible internal combustion engine configurations.

Dye: Are wiring diagrams available for a person setting out to convert their airplane to a Zero powerplant? Is other documentation available?

DeVault: The required rewiring is just extending some cable and removing unnecessary ones. If you are uncomfortable with that level of work, I would not recommend this project. There is no guarantee of information or support from anyone at this time.

There is some required reprogramming, and this requires some special cables and software. I would not tackle this project without the support of someone with the knowledge and tools to do this work.

There is little or no official documentation and support from Zero Motorcycles directly. There are many kind and generous souls who have put a lot of time and effort into aggregating as much information as possible online. Here are the best two sources I know of: www.zeromanual.com and www.electricmotorcycleforum.com.

Dye: Tell us about the reduction drive assembly that you designed. Can a builder get one from you?

DeVault: Yes! You can learn more about it at www.flitllc.com. Sonex is helping me build the re-drive itself. It is the white, welded structure bolted on top of the motor. I will include all the bits required to turn a Zero motorcycle into a complete drive unit: prop hub, adapters, bearings, sprockets, belts and lever throttle. With the possible gearing ratios, you can run approx. 2000–3500 max prop rpm. I even have a connection that can procure a bike from the market and a kit from me, and do all the work for you as a service, providing a turnkey electric drive unit.

Dye: How did you have the engine mount built? Did you draw it up and weld it, or did you have someone else weld it for you?

DeVault: I cut up the existing Sonex motor mount, leaving the landing gear section intact. Then I drew up a new structure in CAD, rough cut the parts and my bud, Bob Mackey, finished and welded it for me. I am not going to sell this part, but I think Sonex may be open to collaborating on it if there’s enough interest. The neat part is, because this conversion is firewall forward, it should fit all their aircraft.

Dye: You’re using a belt reduction drive. What is the reduction ratio, prop rpm and motor rpm you use for cruise?

DeVault: My current reduction is 1.6:1. And honestly, it’s a bit too tall, resulting in more motor heating and less continuous power than possible. I just received my “production sample” parts from my vendor for the new re-drive, and I will change to a 2:1 ratio. That should give approximately 20% more continuous power and lower motor heating in general. In a fairly aggressive climb, followed by minimum-power cruise, peak takeoff rpm is approximately 3100 and best economy cruise is about 1800 rpm. This is all with the Prince P-Tip 56×42-inch prop, which I am pretty darn happy with.

—P.D.

Photos: Paul Dye, Gabriel DeVault and Marc Cook.

Paul Dye, KITPLANES® Editor at Large, retired as a Lead Flight Director for NASA’s Human Space Flight program, with 40 years of aerospace experience on everything from Cubs to the Space Shuttle. An avid homebuilder, he began flying and working on airplanes as a teen, and has experience with a wide range of construction techniques and materials. He flies an RV-8 that he built, an RV-3 that he built with his pilot wife, as well as a Dream Tundra they completed. Currently, they are building a Xenos motorglider. A commercially licensed pilot, he has logged over 5000 hours in many different types of aircraft and is an A&P, EAA Tech Counselor and Flight Advisor, as well as a former member of the Homebuilder’s Council. He consults and collaborates in aerospace operations and flight-testing projects across the country.

For more great content like this, subscribe to KITPLANES!