Rick Adam

Air Force Captain Rick Adam was colorblind, so instead of flying fighter jets he ran the Real Time Computer Center at Cape Kennedy. He was there for Apollo missions 8 through 14, then left the Air Force for a career in computer technology. When he learned to fly in the early ’90s he was so disappointed at the state of the trainer fleet that he decided to design and build a certificated centerline-thrust carbon fiber twin. In this month’s Profile Rick talks with AVweb’s Joe Godfrey about computers, Wall Street, and the path that led to Adam Aircraft’s A-500 Carbon Aero.

George F. "Rick" Adam Jr. was born June 29, 1946, in Pasadena, Calif. His father, a career Air Force officer, flew B-17s and -29s in World War II. Rick grew up on Air Force bases and wanted to follow his father into the cockpit, but a color vision deficiency kept him out of Colorado Springs. Instead he went to West Point, graduated and switched his commission to the Air Force. Captain Adam learned computer science, eventually running the Real Time Computer Centers at the Kennedy Space Center and Vandenberg AFB. During his Air Force stint he attended Florida State University and Golden Gate University and earned his MBA there. After five years in the Air Force, Rick worked in the information technology departments of Baxter Healthcare Corp., FMC, Litton Industries, and IBM. From there he went to Wall Street, ran the IT department at Goldman Sachs, became a general partner and founded the Goldman Sachs Trust Co., Global Custody Business, and Securities Lending Business.He left Wall Street and formed New Era of Networks -- an Enterprise Application Integration software company [ticker symbol NEON] -- took the company public, and eventually sold the company to Sybase. When he learned to fly in the early '90s he was disappointed at the state of the 20-year-old single-engine trainer fleet, and things weren't much better when he graduated to the twin-engine trainer fleet. He decided to take some of the innovation he saw in the single-engine kitplane market and apply it to a certificated centerline-thrust carbon fiber twin. Burt Rutan and Scaled Composites designed the airframe and built the proof of concept model, and Rick expects FAA certification of the A-500 in May or June of this year. Things are moving so fast that Rick uses a Web site to give updates to customers and investors. The planets seem to be lining up for Rick -- one of the biggest orders is from Air Scan, who will use the Carbon Aero to fly range safety missions at the Kennedy Space Center, last year's successful test flight happened to fall on the lucky date of 7/11, and the A-500 isn't the only new twin in the family -- around Christmas Rick and his wife became the proud parents of twins.

How did you get interested in flying? My dad was an Air Force pilot, and flew B-17s and B-29s in the Pacific during World War II. He was headed in for a B-29 replacement crew when the war ended, so they sent his boat to Japan, and I was born right after that. My mom and I went to Japan when I was six months old, we lived there for the first couple of years, and through junior high we just moved around to a series of different Air Force bases where my dad was stationed.

My dad was training B-17 crews in Nellis [AFB] in Las Vegas, and, to conserve fuel, they would they'd take off with multiple crews on board -- gunners, navigators, pilots, bombardiers -- so each crew would get training. One day they're doing one of these training missions around Bakersfield, California, and lost an engine. My dad was the Command Pilot so he put it into Baker Field on three engines. There were a bunch of women at Baker Field being trained as pilots, and they came out to watch this three-engine B-17 come in and land. After they landed my dad called his boss back at Nellis and said, 'I've lost an engine, what do you want me to do?' and his boss said, 'You put it in there; you get it out of there.' They unloaded everything they could truck back and they took off with three engines and flew it back to Las Vegas.A couple weeks later my mom's walking down the sidewalk in Las Vegas and she sees my dad, and says, 'Aren't you that pilot put that B-17 into Baker Field?' and he says, 'Yeah, that's me,' so they started dating, and eventually he said, 'Look, I want you to be my wife and I'll be the pilot.'One day my dad took her up in an AT-6, and they're landing at Nellis and he thinks he's on the intercom, but it turns out he's on the tower frequency. He does this nice landing, and he says, 'How was that for a greaser, honey?' and the tower says, 'Cleared for taxiway 3, honey.' So every time he took off on one of those B-17 missions they called him 'Honey.'I finished high school in Glendale, California -- where my mom went to high school -- then I went to college at West Point. I had wanted to go to the Air Force Academy, but I had a color vision deficiency. Back then the only service academy that would take you if you had a color vision issue was Army. Because my dad had been career Air Force I was able to get commissioned in the Air Force instead of the Army, but I still couldn't fly because of the color vision thing, so I spent five years in the Air Force space program working on computer systems. About half of it was at Cape Kennedy, and the other part of it was at Vandenburg [AFB].What kind of computer systems did you have?

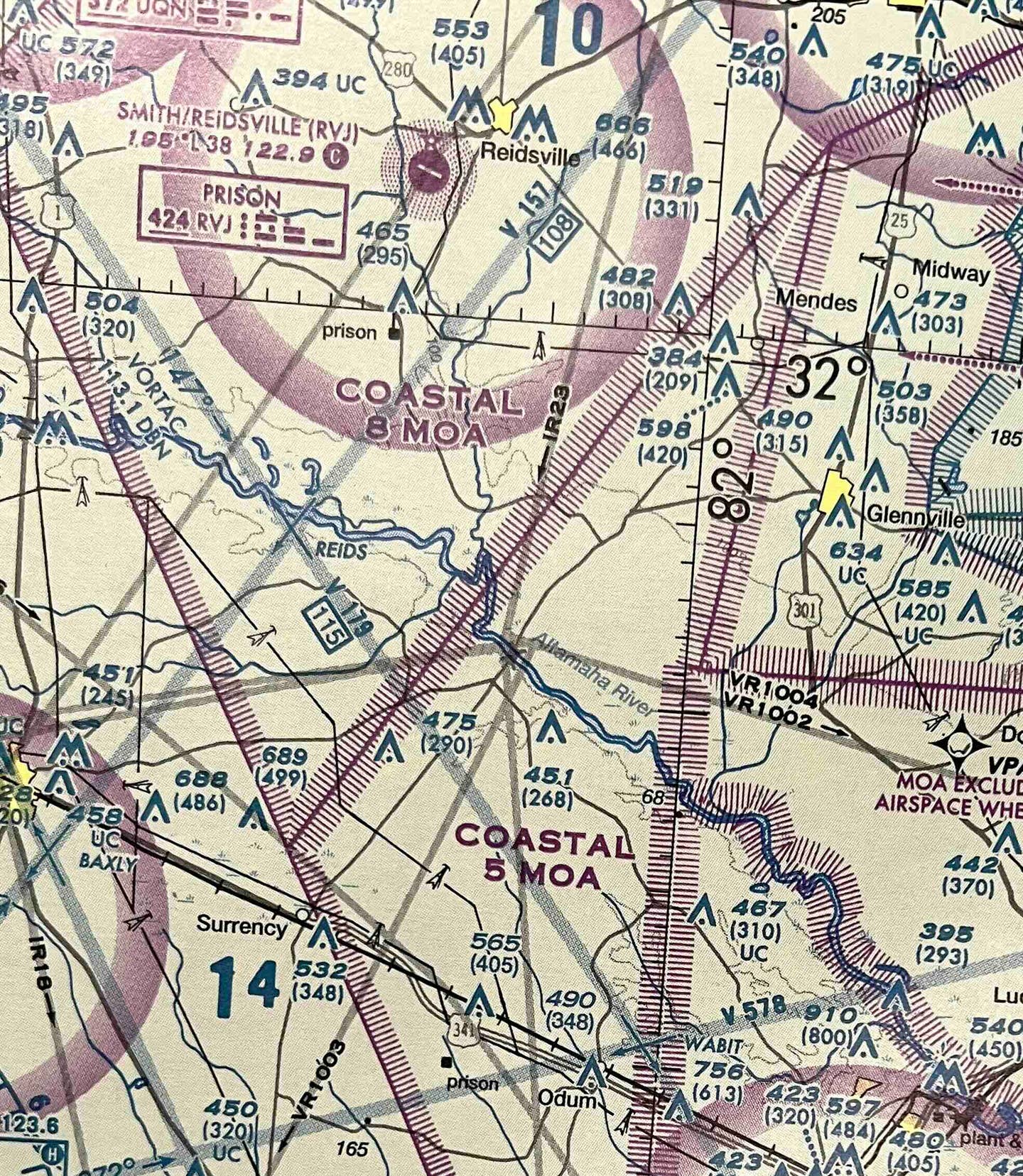

The biggest computer we had was a Control Data 3600, with 36,000 memory locations. Every program we had had to fit in 36K -- the average watch probably has ten times that much now.In the '70s and '80s there were really two different computer missions. During the launch and the active in orbit you had telemetry data and radar data coming down in real time -- position, velocity, acceleration -- that sort of thing -- and then add in any telemetry data that's coming down. For that time, our baud rate was the highest in the world, but it would be considered low now. In addition to the real-time facility, we had a data-reduction facility. While you flew you recorded billions and billions of bytes, and then for months and years afterwards you would data-reduce that. Most of the time I was in the real-time one.Until the vehicle hit escape velocity -- and you knew for sure it was going into orbit -- the Air Force had the ability to destruct anything we flew. If we launched out of Cape Kennedy, for example, and the flight path went right down the cost of Florida, we would regularly have missiles go back and start veering toward Miami, and we had to destruct them and make all the pieces non-aerodynamic before they hit any populated areas. That was always done by an Air Force officer, or a pair of Air Force officers, so the real-time computer center displays told us whether the vehicle was on course or whether it was encroaching on any area where they'd have to blow it up. I was the officer in charge of that.Give us your perspective on Apollo 13. From the Air Force point of view it looked nominal. As soon as the Saturn 5 had escape velocity -- so you know it was going into orbit -- NASA was completely in command of it, so we sat there and watched it for the whole time. The Air Force didn't have a direct role in trying to fix the problem, but it was pretty exciting. The Real Time Computer Center had been put there in an earlier time, so when they put pad 39A and B up -- which is where the Saturn 5s launched -- we were actually inside the blast zone, because they didn't have the money to move the Computer Center. When the thing took off the building would shake like mad and we'd have tiles and lights fall out of the ceiling. I actually never saw a launch for real -- I saw them all on TV 'cause I was down in the blockhouse when they went up.Were you a pilot during this time? I couldn't, because of the color vision thing, so when I got out of the service I took private pilot lessons. I've always been a computer guy so I started a software business. As you're growing up and raising a family it's often hard to find time and money at the same time -- at first I had lots of time and no money, and then after I had money I had no time. Finally, by 1991-92, I was organized enough that I had both the time and the money to fly.My business required me to travel a lot, and I came to the conclusion that the way to build up a lot of hours quickly is to do my business travel by flying myself. So I started in a Skymaster, moved to a Mitsubishi MU2, and then ultimately I stepped up to a Citation jet. I got type-rated in a Citation jet, and literally made hundreds of business trips in those airplanes. In a period of six or seven years I built up well over 1,000 hours, just flying myself on business trips.What motivated you to design and build an airplane? When I first went to take flying lessons I went down to the flight school and said, 'I'd like to take flying lessons.' The guy says, 'No problem,' so we got on the flight line, and there is a 20-year-old 172 there. I said, 'Well, look, I've lot enough money -- I'd rather fly a new airplane.' Then the guy says, 'There aren't any new airplanes,' and I said, 'That can't be,' and he says, 'No, there aren't any new airplanes.'It puzzled me. I've been working in computer technology for 30 years, which has made all this progress, and in my hobby -- aviation -- there's been very little progress over that time, and that just puzzled me. If you study innovation and airplanes you eventually get pulled over where the kit guys are -- Cirrus and Lancair and Glasair and Burt Rutan, all those guys. In the early '90s, all the innovation was being done in composites and kits, then Lancair and Cirrus announced they're going to take what they know how to do in composite kits and build production airplanes. Anybody who loves airplanes was rooting for them, hoping they make it, and sure enough, they both get certified.I'm watching this process and realizing that there is an opportunity to bring new product out in airplanes, and there were quite a few single-engine, non-pressurized, fixed-gear start-ups, but nobody who's trying it in the twin-engine area. So in 1998 I started a company following the lead of Cirrus, Lancair and Glasair and Burt Rutan, with the intent of bringing innovative product into the middle market -- rather than the single-engine market -- of general aviation. It was real clear to me that pilots wanted new product, and once I had seen the success the composite guys had down in single engines, I came to the conclusion it could be done in the twin-engine area.Did you think about relocating the airplane business to somewhere else, or were you determined you could do it in Colorado?

I thought we could do it in Colorado. For the first three years I was working on it, I was also running my software company, which is in Colorado, so really didn't have a lot of choice. In the first two years we did use Burt Rutan and Scaled Composites, so I would regularly fly back and forth to Mojave to see how Burt was doing. Burt built our initial design and our proof of concept airplane. I met with Burt and showed him some requirements, definitions, and preliminary designs, then he came up with four or five design concepts and we narrowed it down to what we have now -- in-line, front and back engine and twin booms to get the tail.What were the other designs like? As always, he had some wild stuff and he had some stuff that was sort of more middle of the road. One had a canard wing with the flight control out at the end of the canard. I said, 'Burt, I got to be able to sell these, so we've got to blend innovative technology with curb appeal so people will buy it.' We worked with him for two years until we started flying our proof of concept airplane. He's a great guy, a very talented guy, and it's an honor to be able to work with him.Were you committed to FADEC engine controls from the get-go? No, we weren't at the get-go 'cause it wasn't announced yet, but, being a lifetime computer guy, it makes a lot of sense to me to control mixture with computers. We're well down the road with Continental and Aerosance on getting that certified, and we'll probably sell our airplanes both ways -- with traditional six levers, and FADEC for people who like something a little more modern. Another option is to go to four levers and control the propeller themselves or go all the way down to two levers and actually have the computer control the propellers also. Once you go down to two levers it looks a lot like a turbine -- forward is go and back is stop -- and it takes away a lot of pilot workload.One of my big bitches is why you see so much innovation in cars and it's so hard to get that level of innovation in airplanes. Cars have had computer controllers on them for 20 years, and they improve mileage, they reduce emissions, they make the engines last longer, so I'm absolutely sure once you start controlling the mixture with the computer you get better fuel economy and you get better reliability, and pilots will be safer.Were you committed to side-stick flight controls from the get-go? We were. Almost all new airplanes have side sticks -- it's very intuitive. Cirrus has it, Lancair has it, every Airbus ever made has it, and I've talked to a bunch of United pilots who come out of 737s and go into Airbuses, and they say there's just nothing to it. You pick it up in five minutes, and the panel is so much more usable when you don't have a big yoke sitting in front of it.Have you had a bump in orders since Eclipse's announcement? No, we haven't, but I anticipate that's going to happen. Some part of Eclipse's backlog are people who really want an airplane soon, and I think we'll be able to fill that need for them.A lot of people were skeptical about using being able to use the FJ-22 in that airplane. Were you one of them? I don't bet against anybody in this business. The -22 is a real breakthrough -- it's twice the performance of anything else ever built, so I think it'll happen eventually, but I think it's going to take a while.The -33 that we're using on our A-700 is a very modest derivative of the FJ-44, which flies all the Citation jets, so I personally have a lot of experience with that engine. It's in production, it's already flying and there are over a million flight hours on that engine, so there's very little risk around that engine.I'm a raging incrementalist, so I think the way to innovate is to take one step at a time. Our engines are traditional, our avionics are traditional, our material is something that the FAA is very comfortable with, so our innovation is the shape of the airframe. We're only innovating in one area -- not three or four. I think once we have that done we can innovate in something else, then we can innovate in something else. It's just so tough to bring a new airplane to market, and you've got to be very careful how much risk you take at one point in time. The Eclipse program was attempting to innovate on three or four different axes and I think that makes it really hard.Have you had stumbles, things you would have done differently in setting up the company and working toward certification? Whenever you innovate or you do unfamiliar things, you literally make hundreds of mistakes. So early on when I started doing entrepreneurial things people would say, 'Well, what's the difference between doing that and being a big company?' and I would say, 'The difference is you make a lot more mistakes and you have to clean up after yourself when you make 'em.'We've changed literally hundreds of things in the program after you try something and it doesn't work -- to be successful you have to be very, very adaptive. But I can't think of anything major we would have done differently. We have a very talented team here -- people who've come out of Cessna, Cirrus, Lancair, Boeing and Scaled Composites, so we have a really good blend of old-timers who've done it the old way and the young turks right out of composite school that know the new way. It's a good blend of gray hair and young enthusiasm.How close are you to certification? We should get it in the spring -- May or June of this year. Our total investment will be around $40 million, which is way less than anybody's ever done this before.How many deposits have you booked? We have around 40 from individuals, another close to 20 from dealers, and an order for 30 from Air Scan, government contractor. They have about 60 flight crew, and about a dozen airplanes that are flying airborne surveillance for the government now. It has come full circle -- they do airborne surveillance for Cape Kennedy and Vandenburg, so during launch phase they stage up and they broadcast real-time video and infrared down to the control center. If there's a Russian trawler or a boat or an airplane in the region, they want to know what it is. These guys can go out and take a look at it.They also have aircraft in Bosnia-Herzegovina, where they're flying for NATO. They download real-time video to the NATO command post, which I think is quite cool. Right now they're flying old aluminum airplanes that can only carry one video camera at a time, but they're going to put two cameras on our airplane -- the government wants them to look at the good guys and the bad guys at the same time.You were at Goldman Sachs through what we now call "the bubble." Give us your perspective on that. Markets have cycled up and down forever, going back to the turn of the century. The American economy was very expansionary through the whole 1990s, and I think the stock market was reflecting the rapid expansion of the economy. If you take away the Internet boom, underneath that the economy really did get a hell of a lot bigger over that 10-year period. In the '70s and '80s, the U.S. economy wasn't very productive, but in the '90s, individual productivity just boomed, and information technology finally started to make a difference in terms of inventory management and production management. So I think the markets obviously got ahead of themselves, but underneath that there was a very solid expansion of the economy. We're cycling now, but the down cycle is not as bad as many we've seen in the last 20 or 30 years, and I think it'll cycle back up.Do you have plans to take Adam Aircraft public?

I'd like to do that -- I took my software company public. The company needs to be profitable, and it'll be a couple of years before we hit that. My guess is in a couple of years the stock market will be more normal, and we'll be grown up enough by that time that we'll look like a good candidate. My first choice on future financing of the company is rewarding our existing investors and our staff -- everybody who works for the company has some stock options.Have you done any innovation in the actual manufacturing process -- have you invented a type of process or something that didn't exist before?We use computer cutters, we use laser placers. If you go into any big aerospace company that's using composites you'll see stuff like we use there. One of the very clever innovations we've made is we've come up with a way to dynamically change our tooling so we can move the wing location. So if we need to move the wing location forward or backward, we just change an offset in one of our tools. That will allow us to adapt a different engine technology over time -- if the engine's weight changes or you go with one instead of two, you can shift the wing location and straighten up the CG without redoing the tooling. That's pretty innovative.Mostly what we've done is taken what's around and put it together in a very effective way. Many people are afraid of carbon fiber layups -- they think it's too labor-intensive. But we've been able to pull an enormous amount of labor out of it. Our carbon fiber wing is 44 feet long and has about 200 part numbers. Compare that to an aluminum wing -- like a Bonanza or a Baron wing -- with about 2,500 part numbers in it. So we have a 90% part count reduction because we're going with composite.One of the places where aerospace has not innovated at all is the seats. We went to the normal guys that build seats and they wanted a ton of money to build them, and they look like they're 30 years old. So we decided to build seats out of three pieces of carbon fiber and four pieces of aluminum. They passed the 26 G and 18 G deceleration tests the first time. They're lighter and stronger, and we saved a ton of money by engineering them ourselves. They'll go on our airplanes, and our salespeople are going to see if we can get some business selling seats to other people.How soon after your type certification will you deliver the first A500? As soon as we get it we'll deliver to our first customer.And how many airplanes do you expect to roll out this year? Assuming we get a mid-year TC, I think we'll get 12 to 18 out this year. Our plan is to quickly ramp up to where we can put out about 50 a year.You flew your inaugural flight on 7/11 last year. Are you superstitious? We had been trying to fly for several days earlier than that, but the way flight tests work is you can't exactly call a date, so it could have just as easily been 7/10 or 7/12, and it happened to be 7/11. That airplane -- Production 1 -- has flown for about 120 hours. We've had it up to 242 knots, which we're really pleased with. It climbs very well on either engine -- front or rear. In the first 120 hours of flight tests we've confirmed that we don't need to change anything, which means all of our production tooling is good. So we're fine-tuning some avionics and some flight controls, but the basic airplane is ready to go, and we'll spend the next four or five months finishing up the rest of the FAA checking.What's your dealer network like? So far we've only signed up one German dealer. We're looking around various parts of the country and whether we're going to go direct. The 40 orders we've done so far have been direct orders -- the way Cirrus, Lancair, and Eclipse have done it. We're looking at some of the stronger dealers in the U.S. and we'll probably have about half direct operation and half dealer operation once we get it figured out.Are dealers are going to be okay with that? We won't compete against them. If we picked up a dealer in southern California, they'd have an exclusive territory and we wouldn't sell against them in their territory.How much maintenance do you expect on your carbon fiber? Is it going to be an easy annual? I think so. It doesn't corrode, it doesn't really fatigue, so the maintenance issues will be the things that move, like the gear and the engines. If somebody damages the carbon fiber, our airplane's very modular, the pieces are easy to get off and on, so we'll have factory replacements that we can quickly send out and just replace the piece they damaged. We'll also have a field repair kit -- and this is well-understood by the FAA -- where you wet layup over the hole -- just like if you have fiberglass boat and you punch a hole in it at the dock. My best guess is if a guy dings a leading edge or a wing tip or whatever, we'll just send him a replacement and an A & P can bolt the old one off and bolt the new one on.It seems like you've had pretty easy sailing with the FAA, at least so far. If you look at what's challenging about bringing an airplane to the market, the aerodynamics are not the challenging part -- the challenge part's the FAA. It's really important to communicate with them early, and establish a relationship of trust with them. Our president, John Knudsen, used to work for the FAA. We worked extremely hard to gain the FAA's trust, and they occasionally ask us to do stuff that's not our first choice, and we just go ahead and do it rather than start an argument. There's lots of ways to skin a cat, and if they have a strong view of doing it one way versus another way, rather than arguing about it we just do it and get on with it. We do have a very businesslike relationship with the FAA, and they're thorough and they're detailed, but I think they're being fair.The FAA is very concerned about the age of the general aviation fleet. The twin-engine fleet is now over 30 years old, and it's getting a year older every year. A guy flying a 30-year-old asymmetrical twin with old engines in it, in my view, is playing Russian roulette every time he takes off. If you lose an engine in our airplane you don't even put your feet on the rudders -- they just sit on the floor. So I think it makes sense for us, for the FAA and for the buying public to have a thorough but an expedited process.Most of us that have ever bought airplanes in our life wish that we had more choice and better value, and that's what we're trying to do -- offer people some really good choices on new stuff to buy.